The Ultimate Sales Guide to Inventory Turn and Inventory Velocity

I’m gonna take a break from economic indicators this week. Parts 1 through 4 of this series can be found below:

- Profit and Loss Statements

- Balance Sheets

- Cash Flow Statements

- Capital Expense Vs. Operating Expense

I had a desire to touch on a company specific topic that will affect many of the people in this community who sell a product.

This week is going to be on inventory velocity. Inventory velocity is the speed or rate at which inventory is cycled with a given period for each item.

Another term I’m going to add to this post is inventory turns. Inventory turns is the rate at which inventory turns in total. Inventory velocity measures the rate at a product level, where inventory turn measures at a divisional or corporate level.

What is Inventory Turn / Inventory Velocity?

Inventory turnover or inventory turn means how many times a company sells and replaces its inventory within a specific time frame.

Here’s the inventory turn formula for your reference: cost of goods sold ($) / average inventory ($).

Cost of goods sold is pretty self explanatory – it’s the total cost of the inventory that was sold during a specific time frame while average inventory is the average value of the inventory held during that same time frame. For example, If you’re cost of goods sold for last year was $10 million and you held, on average, $1 million of inventory in your warehouse:

$10,000,000 / $1,000,000 = 10

What does this mean? Simply put, your inventory turn ratio for last year was 10, meaning you sold and restocked your entire inventory 10 times last year.

Why is Inventory Turn Important to Sales?

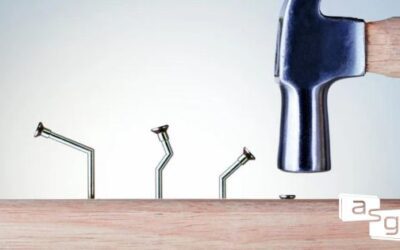

Inventory turn and velocity is an extremely important measure. Simply put, the higher the number or the more “turns” the more profitable (assuming the product is profitable) the company will be. The longer a product sits on the shelf, it is taking up valuable cash nor is it generating cash. It’s dead, it’s not working. The combination of profit and higher turns drives return on sales. Therefore, improving this combination is key to companies. As a salesperson who sells product, you’re ability understand this and address inventory turn is critical.

Imagine you’re a supplier of speakers for headphone and car speaker manufactures. Each of your clients order several types of your speakers, 8 inch round speakers, twitter speakers, ear bud speakers etc. It’s important that your customer has all the speakers they need to meet demand.

But, what happens if they run out of ear bud speakers? How does that affect their relationship with their retail partners? How does that affect sales? The natural solution then might be to increase inventory, but by how much? What happens if they order too much and it ends up sitting on the production floor for two months instead of two days? What is the cost to the company to have inventory sitting around that long? How does it affect their cash-flow? Most importantly, how does it affect your ability to sell to them?

Four Key Metrics that Drive Inventory Velocity:

Planning cycle time

This is basically the order time, the time between when it is recognized a product is in demand and the time it takes to actually get an order to a supplier. If you’re customer needs 8 inch round speakers and it takes 2 days to get the order to you. That’s a problem. The goal is to get order lead time to zero.

Supplier Lead Time

This is all you sales folks. It’s the ability of your company to get what your customers need out the door as fast as possible. In other words, how long from the time you receive an order to get it on the truck and on it’s way to your customer.

Transit Time

Simply put, this is the time it’s en route. How long does it take to go from their dock to your dock.

Variability of Demand

This is the big wild card. Variability in demand is the end customers. End customers can be fickle. It’s the market. Trying to time the market or guess the market is tough. Depending on the customer or demand, it can be consistent, inconsistent, or “lumpy” big orders then nothing all drive the ordering processes.

As a salespeople who sell or affect inventory you should understand inventory turn and velocity as it plays a huge role in your customers business. Inventory velocity and turn affects customer service, cash flow, revenue, profits and more. Knowing the impact your products have or are having on inventory will allow you to sell more as you can build a sales process that fits with the demand for you customers products and can improve their inventory turn.

WITCE – (What is the customers experience?) – Inventory Velocity & Inventory Turn Questions for Sales

1. How often do each of your customers turn inventory?

2. Are their ways you can improve inventory turn with your products?

3. Does your customer struggle with meeting customer demand?

4. Does your customer “send back” product that doesn’t sell and are you stuck with waste?

5. What is your customers supply chain strategy and how well do you integrate into it?

6. Do you consider your customers inventory/supply chain when trying to sell them your products

7. How does your inventory turn/velocity compare to your competitors, does their stuff move faster, slower or the same?

8. Is inventory velocity and turn part of your account management strategy?

9. Are their ways your can improve your customers business by improving the ordering process?

For those salespeople who sell product, there maybe as much selling opportunity in the ordering process as there is in the product itself. Step back for a second and see if your aligned with your customers business. If not, you could be staring at a great opportunity.

Anyone in this community sell products? Would love you to share your thoughts on inventory and how (if at all) it affects your sales process and quota attainment.

0 Comments